Kuraray: Sustainable packaging made of paper and innovative polymers

Author Dr. Bettina Plaumann

Sustainability is the big trend in the packaging market. The focus is on using renewable raw materials, cutting CO2 emissions and developing monomaterial-based packaging. Recyclability and circularity are major challenges. Therefore, the repulpability, recyclability, compostability and biodegradability of packaging are becoming more important.

More sustainability and less use of resources are big challenges for society – worldwide. These days, consumers consciously give preference to sustainable packaging that can be recycled. Big brands and retailers in the food industry such as Danone, Mondelez, Nestlé and Unilever along with Sainsbury’s and Walmart have already issued voluntary commitments on sustainability – the sector has set circular packaging solutions as its goal.

Innovative materials

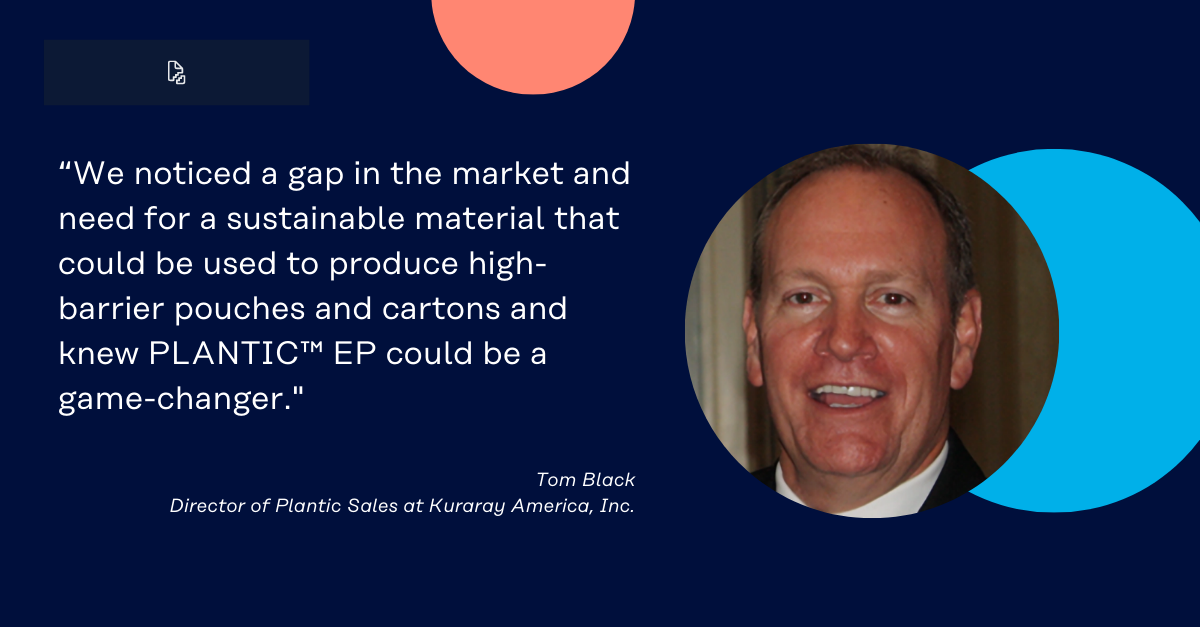

Innovation is key to achieving these objectives. Kuraray’s products and know-how make an essential contribution to the development of innovative packaging. Why continue to package coffee beans in aluminium pouches when paper pouches with a PLANTIC™ layer also provide an excellent barrier to oxygen? PLANTIC™ is a biopolymer derived from starch. Moreover, packaging with water-dispersible, biodegradable PLANTIC™ ensures that paper fibres can be repulped without difficulty.

Another example is EVAL™ – our ethylene vinyl alcohol (EVOH) copolymer. Inserting a barrier layer of innovative EVAL™ SC resin between two layers of polyethylene produces a shrink bag for fresh red meat that is both super transparent and recyclable. The thin layer of EVAL™ EVOH produces particularly light and resource-saving packaging.

Another highlight: Kuraray is the first EVOH producer to offer biocircular EVOH with ISCC PLUS certification. Certification is based on the mass-balance approach and documents the fact that the ethylene monomer in EVAL™ is produced from renewable resources.

PFAS are under scrutiny, and the European Packaging and Packaging Waste Regulation (PPWR) now even bans these substances in food packaging above specific thresholds. Brand owners are therefore on the lookout for new, sustainable solutions. The great news from Kuraray is that PFAS can easily be replaced by EXCEVAL™ in paper-based packaging for dry food. Unlike conventional fluoropolymers, EXCEVAL™ is water-soluble, so this type of packaging can easily be recycled in paper mills.

Just as good – but more sustainable

As a brand owner, you are under pressure to come up with new and more sustainable packaging solutions as quickly as possible, without any reduction in functionality. Here is an example: If you just want to reduce the film layers in multilayer packaging you could simply reduce the weight. However, using thinner layers might mean the packaging no longer has the required barrier properties. What you need are innovative materials.

Kuraray’s products and sector insight can give you completely new options. In our case studies, which you can download below, you can read more about new packaging concepts that successfully combine sustainability with functionality.

We know that every customer has different needs. Your packaging requirements are very specific. And so are the innovative solutions we develop together with you. We’re convinced we can only design the future by working together. That’s what our Innovation Networking Center (INC) is all about. Here, we network our expert knowledge on a global scale within the company and beyond. By networking, sharing knowledge and working together at the INC, we can create value and come up with innovations – with and for our customers.

A global perspective on the sustainability megatrend

Sustainability is the megatrend in the packaging industry. However, it also results in regional differences in the demands made by consumers, legislators and regulators. In recent years, governments in many countries have responded to consumer concerns by endeavouring to reduce packaging waste and improve waste management systems. Unfortunately, the regulations vary greatly from one country to another. At present, there is no global harmonization. Moreover, many countries do not have the necessary recycling infrastructure and processes.

As a brand owner, you may have to adopt new material concepts to make sure your packaging can be recycled locally. For example, repulpable packaging made primarily of paper with only a thin barrier layer can be a worthwhile goal. Ideally, a suitable, water-soluble film should improve the paper fibre yield in the repulping process. Alternatively, you could opt for a monomaterial composite with a very thin yet highly functional barrier layer that does not interfere with common recycling processes. Depending on the applicable regional requirements, such packaging can be recycled as a monomaterial. There are many ways to make your packaging much more sustainable and adapt it to local requirements.

Our approach: A fresh perspective on packaging

Kuraray’s products form the basis for innovative packaging that provides the necessary functionality as well as being efficient and sustainable. We can help you turn your packaging challenges into opportunities.

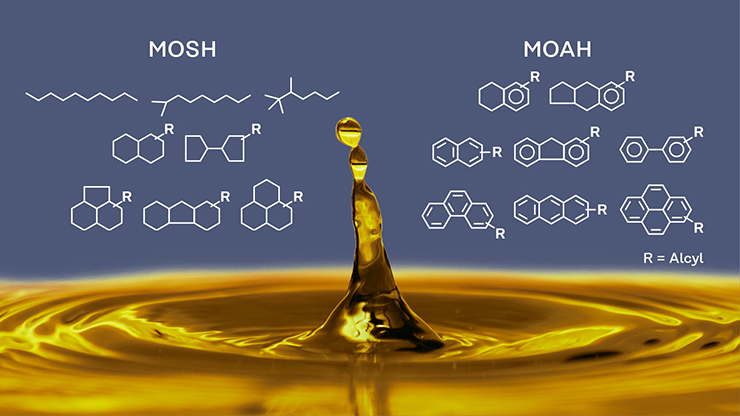

Barrier packaging materials

A barrier is anything that blocks passage, i.e. what leaves or enters the package. Barrier materials are impermeable structures that prevent oxygen and gases flowing in or out, keeping flavours and aromas inside, and contaminants and potential pollutants out. In this way, barriers extend the shelf life of valuable (food) products and help prevent them spoiling and turning into waste.

Barrier packaging is most commonly used to protect food but there are many other goods that are also susceptible to contamination. These include detergents, personal care products such as lotions and shampoos, and many more.

Kuraray offers barrier materials for different processing technologies: from (co-)extrusion, (co-)injection and lamination to coating with films and aqueous solutions. Our portfolio includes bio-based, biodegradable and compostable products, as well as sealing films.

Paper packaging with a barrier layer

Paper packaging is becoming increasingly popular. Not least because these days many consumers routinely recycle paper. As a result, paper has a better image than plastics. Consumers regard paper packaging as more sustainable – and better quality. By using paper packaging, brand owners can show that they take quality and sustainability seriously. However, 100% paper packaging is not generally suitable for food. A suitable barrier layer is needed to resist moisture, oxygen and grease and seal in aroma.

That’s where Kuraray’s innovative solutions come in. Our products help you design customized paper packaging which meets all functional requirements – including for food. In addition, our experts will help you develop paper packaging concepts based on our barrier materials that meet repulpability requirements.

Sustainable plastic packaging

Plastic packaging deserves special attention in the quest to improve the sustainability of packaging. Reducing the amount of material, using plastics made from renewable resources and designing recyclable packaging are important to enhance the sustainability of plastic packaging. Products from Kuraray open up a wide range of possibilities.

We offer materials with a variety of benefits: bio-based, recyclable, water-soluble, fully biodegradable or compostable (industrial or home composting). In many cases, our products can be used for very thin barrier layers. These can greatly reduce the amount of material used in your packaging and even ensure that packaging can be recycled as a monomaterial.

As you can see: plastic packaging has enormous innovative potential. Our products and expertise can help you utilize that potential.

What makes us unique

Kuraray in action

Kuraray offers you a wide range of high-performance materials for functional and sustainable packaging for many different applications and use cases. Our innovative products enable you to overcome your specific sustainability challenges – and even play a key role in your sector.

Get inspired! Download our case studies and find out what’s possible!

Innovative packaging for coffee beans

Facilitate the recyclability of coffee bean pouches by replacing aluminium foil with EXCEVAL™, EVAL™ and PLANTIC™ solutions that retain oxygen and aroma barrier performance.

Dry food packed in paper

Facilitate recyclability of dry food packaging by replacing plastic pouches with KURARAY POVAL™/EXCEVAL™, EVAL™, and PLANTIC™ that ensure an oxygen, moisture, and aroma barrier.

Safe and sustainable packaging for meat

Facilitate recyclability meat packaging by replacing PVDC shrink foil with EVAL™ and PLANTIC™ solutions that fulfil regional preferences and improve shelf-life.

Innovative packaging for dry pet food

Facilitate recyclability of dry pet food packaging by replacing fluoropolymers with EVAL™, EXCEVAL™, and PLANTIC™ solutions that maintain the odour and grease barrier performance.

Innovative packaging for personal care products

Faciltate recyclability of personal care packaging by using Kuraray MonoSol, EVAL™ and PLANTIC solutions that protect shower gels, body creams and lotions from odours and moisture.

Inspired but still have questions? Contact our packaging experts – they will be happy to advise you.

Our key products

From raw materials to ready-to-use films: our products help you find innovative packaging concepts that meet all your functional requirements and greatly increase the sustainability of your packaging. All Kuraray products have their own specific benefits – for example, biodegradability, water-solubility, recyclability, repulpability or compostability.

Events

You can meet experts from Kuraray’s Paper & Packaging team at conferences and trade shows around the world. Take a look at the calendar below – and contact us if you need more information.

Next Events

Our Innovation Networking Center (INC)

From reducing energy usage to adopting recyclable materials, the challenges our customers face in creating a more sustainable future cannot be solved in isolation.

Collaboration, imagination and passion are needed to make positive changes for people and the planet. That will enable us to achieve what no one else can.

INC connects Kuraray’s application expertise and broad portfolio of materials to the unmet needs of our customers. By bridging the gap between the desired end-product and the raw materials that provide the foundations for change, together we can create a more sustainable future.

Since 1926, we have worked to develop innovations for a better tomorrow, solve social issues, and create new value through our business activities. Through the INC, we are fulfilling our desire to discover and co-create new solutions with our partners – working together towards a fairer, safer and more sustainable future. Drawing on decades of expertise to tailor each solution to your unique needs. We use our comprehensive range of resources and service offerings to turn your next ambitious idea into reality.

You have ideas for ground-breaking solutions and are looking for a sparring partner to help you channel your innovations in the right direction?

Contact our experts at the INC right now!

Sustainability at Kuraray

Kuraray has a clear vision: as a sustainability leader, Kuraray will develop innovative solutions with unique products and cleaner technologies to improve the natural environment and enhance quality of life for people everywhere.

Working to enhance sustainability has many facets. At Kuraray, it has four dimensions: the planet, people, products and prosperity. Our plan is to improve the natural environment, create integrative jobs, enable innovation for sustainable products and build and promote a prosperous society.

To fulfil our climate responsibility, we at Kuraray intend to reduce our greenhouse gas emissions by 30 percent by 2030 (compared with 2019) and to be climate-neutral by 2050. By 2026, we plan to generate 60 percent of sales with products that make a contribution to protecting the environment. In 2020, such products accounted for 46 percent of sales.

In short, sustainability is firmly rooted in Kuraray’s corporate culture.

Rigid and flexible packaging

Packaging materials from Kuraray give you the freedom you need to design functional packaging for your products. Almost any shape is possible: tubs, pouches, bottles, bag-in-box, trays, pods, fruit sleeves … the possibilities are endless. Whatever you opt for, our technical experts can help you develop the optimal packaging structure. That’s why Kuraray is the ideal choice for brand owners and packaging producers. The benefits are clear: you gain a flexible, top-performing partner that offers a full range of sustainable products – backed up by extensive sector insight and technological know-how. That saves you time and money in the development of sustainable and innovative packaging. We can help you meet all the demands made on your new packaging – with optimal products from Kuraray.

Real benefits

Our broad spectrum of innovative packaging materials makes it possible to develop new packaging solutions tailored specifically to your requirements. No matter what your sustainable paper or plastic packaging should look like: our materials offer real benefits.

Looking for a solution tailored specifically to your needs? Thanks to our extensive product know-how, we can help you define and develop exactly what you’re looking for. The local experts in Kuraray’s global Paper & Packaging team are always ready to work with you to redesign your packaging: to increase efficiency, functionality and sustainability. We offer the right combination of materials to balance the functional and regulatory requirements made on your packaging.

You can rely on us: we have plenty of ideas for innovative solutions for a more sustainable future. With Kuraray at your side, you will find the right answers – to new packaging and recycling regulations, supply chain requirements, and consumers’ rising sustainability requirements.

We are convinced that “You can’t create the future alone.”

Contact us – we’re always here for you!

News

Here you can find press release and publications for the paper and plastic packaging industry. Please contact us if you have any questions.